Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Submersible pumps are essential in various industries for fluid management. Their unique ability to operate underwater makes them incredibly efficient.

In this article, we will explain how a submersible pump works, its key components, and the advantages and challenges of using one.

By the end of this article, you’ll understand how to choose the right submersible pump for your needs.

A submersible pump is a type of pump that is completely submerged in the fluid it is pumping. Unlike traditional pumps that sit above the fluid and rely on suction, submersible pumps push the liquid upwards using a motor that is hermetically sealed to prevent water from entering and damaging the motor. This unique design allows the pump to operate efficiently while being fully submerged in the fluid.

The main components of a submersible pump include:

● Motor: The heart of the pump, responsible for driving the impeller.

● Impeller: A rotating part that moves the liquid.

● Pump Housing: The outer casing that contains and protects the pump components.

Submersible pumps are versatile and used in various industries for different applications:

● Agriculture: Submersible pumps are commonly used to extract groundwater from wells for irrigation purposes.

● Residential Water Supply: They can pump water from wells to homes or remove excess water from flooded areas.

● Sewage Treatment: These pumps are ideal for handling wastewater, including solids and slurry.

● Dewatering: Submersible pumps are frequently used in construction, mining, and flood management to remove water from deep wells, construction sites, or flooded basements.

Submersible pumps differ from other types of pumps, such as centrifugal or jet pumps. Unlike centrifugal pumps, which rely on suction to pull water into the system, submersible pumps push water from the bottom of the fluid reservoir. This submerged design eliminates the need for priming and provides more efficient operation with less energy consumption. Jet pumps, on the other hand, require more maintenance and have higher energy demands since they operate above the fluid's surface.

A submersible pump is designed to be fully submerged in the fluid it pumps, whether it's water, sewage, or slurry. The immersion allows the pump to operate without worrying about the cavitation issues that often affect surface pumps. The fluid surrounding the pump helps cool the motor, ensuring efficient operation.

When the submersible pump is switched on, the motor receives electrical energy from an external power source. The motor, which is sealed to prevent water ingress, transfers the power to the impeller through a shaft. The impeller, which consists of multiple blades, starts to rotate rapidly, creating centrifugal force that moves the liquid towards the pump's discharge.

The impeller’s rotation increases the velocity of the fluid, causing it to gain kinetic energy. This action helps push the liquid out of the pump towards the discharge outlet.

Once the liquid reaches the impeller, it flows through the diffuser, a stationary component designed to convert the kinetic energy of the liquid into pressure energy. This transformation increases the pressure of the fluid, making it possible to transport the liquid through pipes and to the desired destination.

The pressurized liquid is then discharged from the pump through the outlet valve or pipe. The system continues to work as long as it receives power, maintaining an efficient flow of liquid.

Step | Description |

1. Immersion in Fluid | The pump is fully submerged in the liquid to be pumped, eliminating cavitation and improving efficiency. |

2. Motor Activation | The motor is powered by electricity and drives the impeller to begin rotation. |

3. Impeller Function | The impeller creates centrifugal force to move the liquid towards the discharge. |

4. Fluid Movement | As the impeller moves the liquid, it gains kinetic energy, which is converted to pressure in the diffuser. |

5. Discharge of Fluid | Pressurized fluid exits through the pump’s outlet and is directed to the desired location. |

The motor in a submersible pump is a vital component, as it drives the impeller. Since the pump operates underwater, the motor is hermetically sealed to protect it from the surrounding liquid. This sealed design prevents water from entering and causing short circuits or corrosion. The motor is typically filled with oil to enhance cooling and provide additional protection from water damage.

The impeller is the part that moves the liquid, and it is directly connected to the motor. As the motor spins, the impeller's blades rotate, creating a centrifugal force that pushes the liquid through the pump. The diffuser, positioned after the impeller, plays an essential role in converting the liquid's kinetic energy into pressure. This pressurization allows the pump to transport the liquid more efficiently.

Seals and bearings ensure smooth operation by reducing friction and preventing water from reaching the motor. The intake screen is an essential part of the system, as it filters out large debris and particles that could potentially clog the pump or damage the components. The seals and bearings also ensure that the pump operates with minimal wear, extending its operational life.

The housing is the outer casing that contains and protects all the internal components of the pump. It is typically made of durable materials like stainless steel or high-strength plastic to withstand the harsh conditions of being submerged in water or other fluids. Corrosion-resistant housing materials are crucial for ensuring the pump's longevity, especially in applications where the pump is exposed to abrasive or corrosive fluids.

Component | Description |

Motor | Powers the impeller, converting electrical energy into mechanical movement. |

Impeller | Rotating component that moves the liquid, creating centrifugal force. |

Diffuser | Converts kinetic energy into pressure, enabling efficient fluid movement. |

Seals & Bearings | Prevent water from entering the motor and ensure smooth operation. |

Pump Housing | Encases and protects internal components, often made of corrosion-resistant materials. |

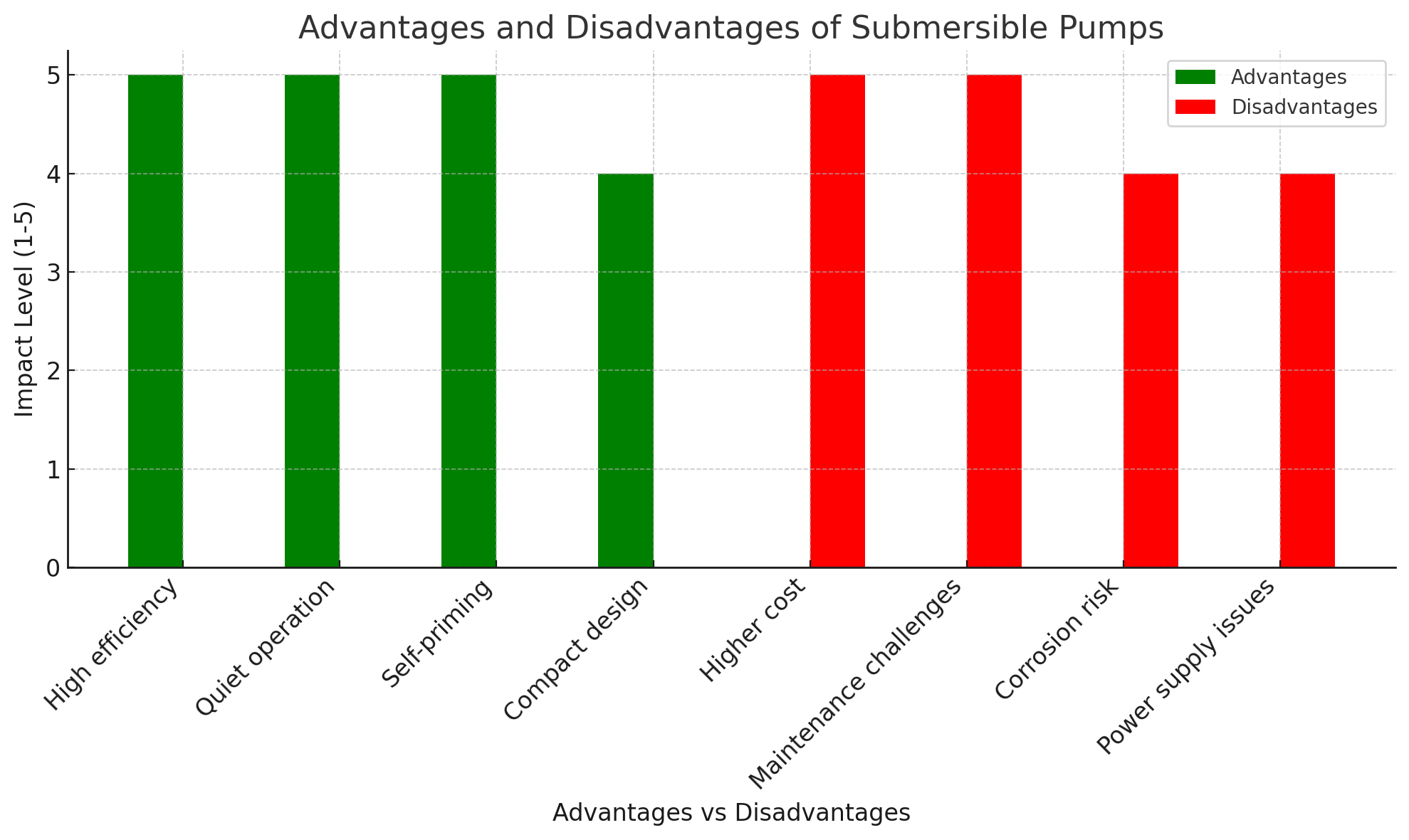

Submersible pumps are highly efficient because they operate fully submerged in the fluid. This eliminates the need for suction, allowing the pump to push the liquid with less energy. As a result, submersible pumps consume less power and offer superior performance compared to surface-mounted pumps.

One of the key benefits of submersible pumps is their ability to operate in deep wells, offering consistent water flow even at significant depths. They also provide a higher flow rate, making them suitable for applications that require large volumes of liquid to be moved quickly.

Unlike traditional pumps, submersible pumps do not need to be primed before use. Since the pump is already submerged in the fluid, it can start pumping immediately, providing hassle-free operation. This self-priming capability reduces maintenance and ensures that the pump is always ready for use when needed.

Submersible pumps are known for their quiet operation. Since they are submerged in the fluid, the sound of the motor and impeller is muted, making them ideal for noise-sensitive environments such as residential areas, offices, or hospitals. This quiet feature is especially useful when pumps are in continuous operation, such as in wastewater treatment plants.

The compact design of submersible pumps allows them to be installed in small, confined spaces where larger pumps cannot fit. They are versatile and can handle various applications, from dewatering basements to pumping sewage or slurry. Their adaptability makes them a popular choice for both residential and industrial use.

Submersible pumps typically come with a higher upfront cost compared to other types of pumps. The motor and sealing mechanisms required to operate underwater can make these pumps more expensive. However, their energy efficiency and reduced maintenance needs often offset the higher initial cost over time.

While submersible pumps are designed to be durable, accessing them for maintenance or repairs can be challenging. Since they are submerged in the liquid, specialized equipment may be required to remove and inspect the pump. Regular maintenance is essential to ensure the pump's longevity and efficiency, but it can be more complicated compared to surface-mounted pumps.

Exposing submersible pumps to harsh chemicals, abrasive particles, or high temperatures can lead to corrosion and material degradation. While many pumps are made from corrosion-resistant materials such as stainless steel, extended exposure to corrosive substances can reduce their lifespan. Regular inspections and maintenance are crucial to prevent this.

Submersible pumps require a stable and uninterrupted power supply to function optimally. Any power fluctuations or interruptions can affect their performance, making them less reliable in areas with unstable electrical grids. Environmental conditions, such as high water temperatures or the presence of aggressive chemicals, can also impact the pump's efficiency and longevity.

Submersible pumps are widely used in agriculture to extract groundwater for irrigation purposes. Their ability to operate at significant depths and pump large volumes of water efficiently makes them ideal for agricultural applications. These pumps ensure a consistent water supply for crops, improving productivity and supporting sustainable farming practices.

In sewage treatment plants and wastewater systems, submersible pumps are used to handle wastewater and sewage. Their design allows them to efficiently handle both liquids and solids, ensuring that wastewater is properly managed and treated before being released into the environment.

Submersible pumps are essential in emergency dewatering applications, such as removing water from flooded areas or construction sites. Their portability and efficiency make them ideal for quickly draining water from basements, tunnels, or other flooded spaces.

Submersible pumps are used in a variety of industrial applications, including oil extraction, slurry pumping, and the handling of corrosive or abrasive fluids. Their ability to operate in harsh environments, including high temperatures and corrosive conditions, makes them valuable in industries such as mining, oil and gas, and manufacturing.

Submersible pumps are essential for fluid management in various industries. They provide high efficiency, quiet operation, and versatility, making them ideal for applications ranging from residential water supply to industrial slurry pumping. When selecting a submersible pump, factors such as fluid type, flow rate, and environmental conditions should be considered. SRM offers reliable submersible pumps designed for long-lasting performance and efficiency, ensuring that your needs are met with exceptional value.

A: A submersible pump is a type of pump designed to operate fully submerged in liquid, pushing the fluid through a system rather than pulling it, which improves efficiency.

A: A submersible pump works by using a motor to power an impeller, which moves liquid through the pump. The liquid is pushed from the pump’s intake to its discharge outlet under pressure.

A: Submersible pumps are more energy-efficient because they operate underwater, reducing the need for suction. They are also quieter and ideal for tight spaces.

A: Yes, submersible pumps can handle both clean and dirty water. However, the model should be chosen based on the type of liquid and its contents.

A: Submersible pumps are used in agriculture for irrigation, in residential areas for draining flooded basements, and in industrial settings for handling wastewater and slurry.

A: Consider the type of fluid, the required flow rate, the environmental conditions, and the pump's power rating to ensure efficient and reliable performance.

A: With proper maintenance, a submersible pump can last anywhere from 8 to 15 years, depending on the usage and the conditions in which it operates.