What is a surface pump, and why does it matter? Many farms, homes, and work sites rely on this tool for simple water transfer. It uses suction to lift water from shallow sources. In this article, you will learn how surface pumps work and where they fit best. Brands like Shanghai People Enterprise Group Pump Co., Ltd. offer reliable options—learn more about our products.

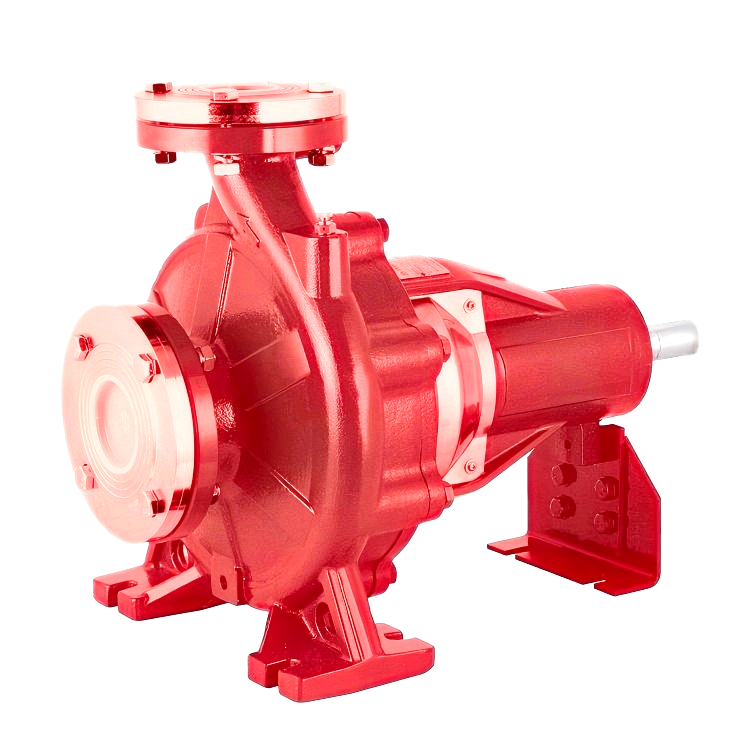

A surface pump is a mechanical device placed above the water source. It draws water from rivers, ponds, tanks, or shallow wells and sends it to another location. Its goal is fast and dependable water transfer for a wide range of tasks. People use it in farming, home water systems, landscaping, and construction drainage. Unlike deep-well systems, it relies on air pressure and suction instead of pushing water from beneath the surface. This makes it simple to install and operate in areas where water is easy to reach.

Surface pumps stay dry and sit on the ground, making them easy to access for inspection or repair. Submersible pumps operate underwater and push water upward from greater depths. Surface models often cost less and are easier to maintain, while submersible pumps work better in deep wells and tend to run more quietly. The choice depends on water depth, accessibility needs, and operating conditions.

A surface pump for shallow wells works best when the water level is within about 7 to 8 meters. At this depth, suction remains stable, allowing smooth and continuous flow. Ponds, streams, rainwater tanks, and small reservoirs also suit this setup well. Because installation is simple and does not require underwater work, users can position or relocate the pump with minimal effort. This flexibility benefits homes, farms, and temporary sites.

Surface pumps address common issues such as low household water pressure, slow irrigation flow, or pooling water at construction areas. They move clean or lightly dirty water efficiently, supporting daily tasks and seasonal operations. Users often rely on them for emergency water transfer, garden watering, and small-scale dewatering. Their portability makes them useful for short-term projects and changing site conditions.

Surface pumps offer easy access, quick installation, and low upfront cost. Maintenance is straightforward because all components remain above the water. They perform well in shallow environments and support many residential and light industrial needs. However, they cannot lift water beyond roughly 25 feet due to suction limits. Noise levels can also be higher compared with underwater systems. Knowing these strengths and constraints helps users choose the right pump for long-term performance.

Feature | Surface Pump | Submersible Pump |

Installation | Above ground | Underwater |

Best Depth | Shallow sources | Deep wells |

Maintenance | Easy access | Harder access |

Noise Level | Higher | Lower |

Cost Range | Lower to medium | Medium to high |

When the pump starts, it creates a low-pressure zone inside the suction line. This vacuum effect pulls water upward from the source. Atmospheric pressure helps push the water into the hose, allowing the pump to lift liquid efficiently from shallow locations. This mechanism is simple but highly effective for most surface-level water transfer tasks.

The motor drives a rotating impeller that adds energy to the water. As the impeller spins, it accelerates the water outward and increases its pressure before directing it into the discharge pipe. This process produces a steady, controlled flow to the target point. Many modern centrifugal designs use balanced rotors and optimized hydraulics to reduce vibration, enhance efficiency, and extend component life under continuous operation.

Priming removes air from the pump and fills the chamber with water. Without priming, the pump may run dry and fail to generate suction, which can damage internal parts. In environments where water levels vary or systems stop and restart often, self-priming pumps offer strong advantages. They automatically restore suction after air enters the system, reducing manual effort and downtime.

Centrifugal pumps rely on a rapid-spinning impeller to move large volumes of clean water. They are well suited for irrigation systems, cooling circuits, and tank filling operations. Reinforced materials such as cast iron or stainless steel help these pumps withstand demanding use and extend their service lifespan.

Jet pumps are commonly used in shallow well setups and household water systems. They provide strong suction and support daily needs like showers, faucets, and garden irrigation. Their pressure-boosting ability makes them a practical choice for small residential properties and locations with low natural water pressure.

Self-priming models maintain suction even when air enters the line. This makes them ideal for construction sites, portable irrigation systems, and seasonal drainage where conditions change frequently. They help users avoid repeated manual priming and offer more consistent operation.

Positive displacement pumps move a fixed volume of liquid with each cycle. They are suited for thicker or more controlled-flow fluids often found in industrial settings. Their precise output makes them valuable for metering, dosing, and applications involving higher-viscosity liquids.

Pump Type | Best Use Case | Flow Strength | Water Quality |

Centrifugal | Irrigation, cooling systems | High | Clean |

Jet Pump | Homes, shallow wells | Medium | Clean |

Self-Priming | Temporary jobs | Medium | Clean to light debris |

Positive Displacement | Industrial fluids | Low to medium | Thick or mixed |

Farmers use surface pump applications in irrigation to move water from nearby sources to their fields. These pumps support sprinklers, drip lines, and other delivery systems with steady flow. They also help maintain supply during dry seasons when groundwater is limited. With reliable water movement, farms can manage crops more effectively across changing conditions.

Many surface pumps are lightweight and easy to transport. This mobility supports crop rotation, temporary irrigation zones, and flood control during heavy rains. They also serve well in short-term projects where quick setup and removal are important.

A consistent water supply improves soil moisture, helping crops grow evenly. Surface pumps reduce waste by delivering controlled flow to each area. Over time, this supports healthier plants and more efficient use of available water resources.

Low pressure can affect showers, taps, and appliances. A surface pump provides stronger, more stable flow, making daily water use smoother and more comfortable.

Homes with nearby shallow wells often rely on these pumps to draw water easily. They offer stable supply without complex installation, making them suitable for rural and suburban properties.

Surface pumps act as emergency support during outages. They can fill storage tanks or provide temporary flow for essential tasks, including fire safety systems in isolated areas.

Tip: For residential systems, a self-priming jet pump reduces startup issues and helps maintain stable pressure during peak use.

Builders use surface pumps to remove unwanted water from trenches, pits, and work zones. This keeps areas safe, prevents delays, and supports consistent progress on the project.

Factories use surface pumps for cleaning processes, cooling loops, and water circulation systems. High-efficiency models can help reduce overall energy use in large industrial setups.

In drilling and other short-term operations, surface pumps move return fluids and support tank transfers. Their portability and strong flow make them useful in dynamic work environments.

Start by checking how far water must rise to reach the pump. Measure the flow needed per hour for your system. These values determine the appropriate pump size and motor capacity.

Clean water works well with centrifugal or jet pumps. Applications involving thicker or mixed fluids may require positive displacement designs or added filtration.

Electric models suit homes, small farms, and factories. Gas or diesel pumps offer strong performance in remote areas where access to electricity is limited.

Factor | What to Check | Why It Matters |

Suction Depth | Height from source | Prevents loss of flow |

Flow Rate | Liters per minute | Meets demand |

Power Type | Electric or fuel | Matches site access |

Water Quality | Clean or mixed | Protects pump parts |

Inspect seals, hoses, and fittings often to avoid leaks and suction loss. Clean filters after heavy or dirty-water use to maintain flow stability. Regular lubrication and routine checks help prevent early wear. Industrial models with modular designs also make part replacement faster and reduce downtime.

Loose joints or damaged hoses can introduce air into the system, which reduces performance and increases noise. Cavitation may appear when suction lines are restricted or water levels drop too low. Tightening connections and ensuring proper priming are simple ways to reduce these issues and protect internal components.

Store pumps in dry, clean areas to protect electrical parts. Keep suction lines straight, properly sealed, and free of debris. Use high-quality mechanical seals to prevent leakage and overheating. Routine inspections help maintain stable output and extend overall pump service life.

Note: Pumps with certified energy ratings and quality seals often show lower lifecycle costs in long-term industrial use.

Most models lift water up to 25 feet. Beyond this depth, suction weakens and overall flow drops.

Surface pumps handle light debris only. For heavy solids or sludge, a trash pump is a better choice.

Some industrial-grade surface pumps are designed for continuous use. Always check the duty rating before running a pump for extended periods.

Now you know what a surface pump is and why it matters. It moves water from shallow sources for farms, homes, and industrial sites. It supports irrigation and daily supply with simple, reliable performance. Brands like Shanghai People Enterprise Group Pump Co., Ltd. offer durable, efficient products that add long-term value. Choose the right model to keep your system running smoothly.

A: A surface pump moves water from shallow sources like ponds or wells. This makes it ideal for irrigation and surface pump applications in irrigation.

A: A surface pump uses suction to lift water, unlike submersible pumps. This method supports tasks such as surface pump for domestic water supply.

A: A surface pump offers easy maintenance and strong performance for shallow wells. Many users rely on it for surface pump for shallow wells.

A: A surface pump may fail if priming is lost or air enters the line. Check seals and hoses, especially in surface pump working principle explained scenarios.