Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

Submersible pumps are widely used for moving water and other liquids in various applications. However, in colder climates, a common concern is whether these pumps can freeze.

In this article, we will explore the risks of freezing, its impact on pump functionality, and how to prevent damage.

By understanding these challenges, you can ensure your submersible pump operates efficiently throughout winter.

A submersible pump is designed to operate while submerged in the fluid it is pumping. The pump's motor is sealed in a waterproof casing to prevent water from coming into contact with electrical components. Submersible pumps are typically used in applications such as pumping water from deep wells, draining flooded areas, and moving sewage. Their ability to work underwater eliminates the need for priming, and they can efficiently push liquid, reducing energy consumption compared to other pump types.

Submersible pumps work by using the surrounding liquid’s pressure to push the liquid into the pump. Because the pump is submerged, it doesn't need to work against atmospheric pressure, making it more efficient. This design also reduces the chance of cavitation (air bubbles in the pump), a problem common in pumps that draw water from above.

Submersible pumps are favored in industries for their efficiency, especially in deep well pumping, where they provide continuous water supply without the need for a priming mechanism.

Submersible pumps are generally designed to work submerged in water, and the surrounding water provides some protection against freezing. However, there are situations where freezing can still occur, especially when water temperatures drop below freezing for extended periods. When water freezes, it expands, potentially causing severe damage to the pump's components. The pump body, motor casing, or connected pipes can crack due to the expansion of ice, leading to costly repairs or replacement.

Water that remains stagnant in the pipes or pump can quickly freeze when temperatures drop. This is especially true for systems installed outdoors or in areas where the ground does not provide enough insulation to keep the water from freezing.

Freezing in submersible pumps typically occurs when the temperature of the water drops below 32°F (0°C), especially in outdoor installations. In colder climates, this can happen during the winter months when the pump and pipes are exposed to freezing temperatures for prolonged periods.

Submersible pumps installed in regions with ground temperatures that dip below freezing are particularly vulnerable if they are not properly insulated or maintained. Similarly, pumps left in waterlogged areas during winter months or pumps used in seasonal applications without winterization are at a higher risk of freezing.

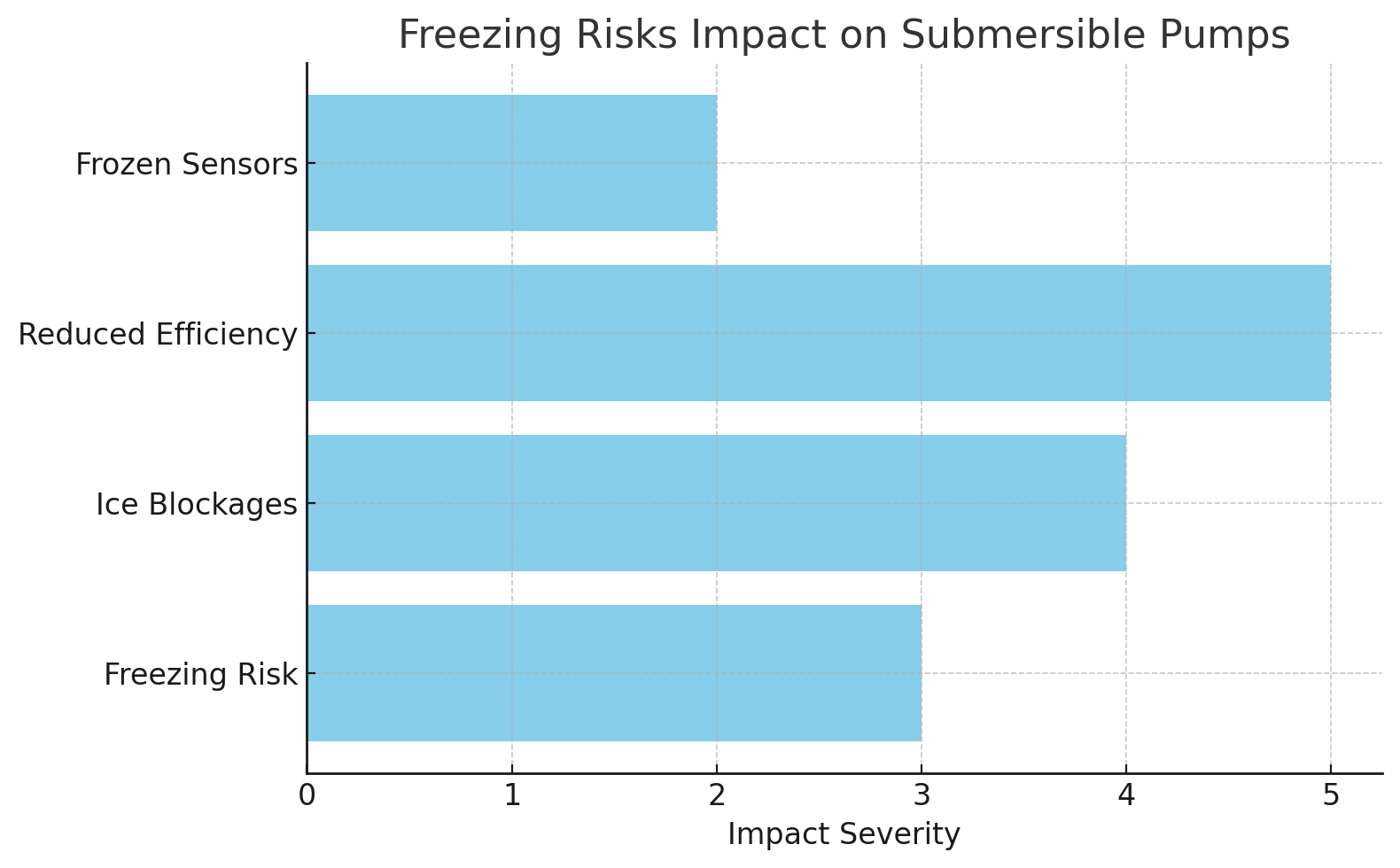

When water freezes in or around a submersible pump, it can cause significant damage. The most common issues include:

● Cracking of Pump Housing and Pipes: As water expands during freezing, it puts immense pressure on the pump casing and the pipes. This pressure can crack the housing and pipes, rendering the pump inoperable.

● Jamming of Moving Parts: Frozen water can cause mechanical parts within the pump, such as impellers or seals, to become stuck. This can result in the pump failing to function correctly or even permanently damaging internal components.

These issues often lead to costly repairs, significant downtime, or even the need to replace the entire pump.

When a submersible pump is exposed to freezing conditions, it can work harder than normal to try and push the fluid through the system. Ice buildup can restrict the flow of water, causing the pump to overheat. This results in increased energy consumption and can put unnecessary strain on the motor, potentially causing it to burn out.

Freezing can also affect the sensors and electrical components of the pump. For example, if the temperature sensor freezes, the pump may operate inefficiently or fail to turn on at the correct time, resulting in further complications.

Risk Factor | Impact Type | Protective Measures |

Water freezing and expanding | May cause pump housing or pipes to crack | Drain water, use insulation for protection |

Ice blockages in moving parts | Can cause pump malfunction or failure | Regularly inspect pump for ice blockages |

Reduced efficiency in cold temperatures | Requires more energy to operate | Use heating tape, ensure surrounding temperature is above freezing |

Ice-covered pump sensors | May lead to inaccurate measurements, affecting performance | Use anti-freeze oil, keep pump components warm |

Winterization is the process of preparing your submersible pump for the colder months to prevent freezing. Here’s how you can winterize your pump:

● Drain the Pump: Ensure that the pump is fully drained before storing it for the winter. Any residual water left in the pump or pipes can freeze, causing damage.

● Apply Antifreeze: Use a non-toxic antifreeze solution suitable for your pump system to prevent water from freezing inside the pump.

● Insulate: Insulating the pump and surrounding pipes will help protect them from extreme cold. This can include using insulating jackets, foam wraps, or even burying the pipes below the frost line.

● Use Heating Systems: In areas with extreme cold, heating cables or heat lamps can be used to keep the pump and pipes above freezing. This method is especially useful for pumps left exposed to the elements.

Step | Description | Purpose |

Drain the pump | Drain water through valves or discharge ports | Prevent freezing and pump casing damage |

Use antifreeze | Add non-toxic antifreeze to the pump housing | Protect pump and components from freezing |

Keep the pump warm | Use heating tape or insulation to warm the pump | Prevent freezing and damage to pump parts |

Store in a warm environment | Ensure the pump is stored in a dry, warm place | Prevent freezing and maintain pump condition |

If the pump is not in use during the winter, it is essential to store it in a dry, well-insulated area. This prevents moisture from accumulating and freezing in the pump's internal components. Make sure to:

● Disconnect the Pump: Remove the pump from the water and disconnect it from the power source before storage.

● Dry the System: Thoroughly dry all components, including the pump, pipes, and cables, to prevent ice from forming inside.

● Store in a Warm Area: If possible, store the pump in a temperature-controlled environment that remains above freezing.

Regular inspections are crucial to ensuring the submersible pump remains free of ice damage. Check for any cracks, leaks, or signs of wear and tear, especially before and after winter. Pay particular attention to the seals and gaskets, as these are more vulnerable to freezing conditions. Monitoring the performance of the pump during cold weather can also help detect early signs of malfunction.

Cold weather can lead to power outages, which may disrupt the operation of your submersible pump. To avoid failure during freezing conditions, it is recommended to install a backup power supply such as a generator or uninterruptible power supply (UPS). This ensures the pump can continue functioning without interruption, preventing freezing from causing additional issues.

If your submersible pump freezes, it is important to thaw it carefully to avoid causing further damage:

● Use Heat Lamps or Heat Tracing: Gradually warm the pump and pipes using heat lamps or specialized heat tracing cables. Never use direct flame or excessive heat, as this can damage the pump components.

● Thaw Slowly: Allow the pump to thaw at its own pace, ensuring that it does not suffer from thermal shock, which can crack the housing.

If your pump has been damaged by freezing, it is essential to inspect the affected areas. Look for:

● Cracks in the Pump Housing: If the housing is cracked, it is best to replace it immediately.

● Damaged Impellers or Seals: Frozen components may cause permanent damage, necessitating replacement.

● Check the Motor: If the motor has been affected by ice, it may require professional inspection to assess the level of damage.

Regular checks and early intervention can prevent costly repairs and extend the life of your submersible pump.

Submersible pumps used in deep wells and sewage systems are particularly vulnerable to freezing. These pumps often operate in harsh environments, and any disruption in water flow due to freezing can lead to significant issues. Sewage pumps, in particular, face the additional risk of blockages caused by freezing in the discharge lines, which can lead to system failures.

Pumps used in industrial and agricultural settings, such as those for water drainage or irrigation, also face challenges in freezing temperatures. Industrial pumps, which operate in locations where water often stands for extended periods, are more susceptible to ice damage. These systems must be carefully monitored, especially during winter months, to ensure that they continue to operate efficiently.

Pump Type | Features | Suitable Environments |

Submersible Well Pumps | Designed for long-term submersion, ideal for cold climates | Used for deep well water extraction in residential or industrial applications |

Dewatering Pumps | Handles large water flows, suitable for low temperatures | Used on construction sites or in underground garages in cold environments |

Sewage Pumps | Handles corrosive liquids like sewage, mud, etc., with freeze-resistant features | Ideal for sewage systems in cold climates |

Freezing poses a significant risk to submersible pumps, but with proper winterization and maintenance, you can prevent damage. Draining the pump, adding insulation, and storing it correctly are key preventive steps. Regular inspections and backup power systems also ensure pump longevity. By addressing freezing risks, you can maintain the efficiency and reliability of your submersible pump. For high-quality pumps and expert service, SRM offers reliable solutions that keep your pump running smoothly in all conditions.

A: Yes, a submersible pump can freeze in extreme cold if not properly winterized. Frozen water inside the pump can cause cracks, blockages, or damage to moving parts.

A: To prevent freezing, drain the pump, insulate it, and store it in a dry, well-ventilated area. Regular inspections and backup power systems can also help.

A: Freezing can cause water to expand, leading to cracks in the pump housing or pipes. It can also block moving parts, reducing efficiency and potentially causing failure.

A: When not in use, store the submersible pump in a dry, insulated, and frost-free location. This helps avoid freezing and ensures the pump remains in good condition.

A: Yes, but only if it's properly winterized. Insulating the pump and pipes, as well as ensuring the pump is fully drained, will help it function in freezing conditions.